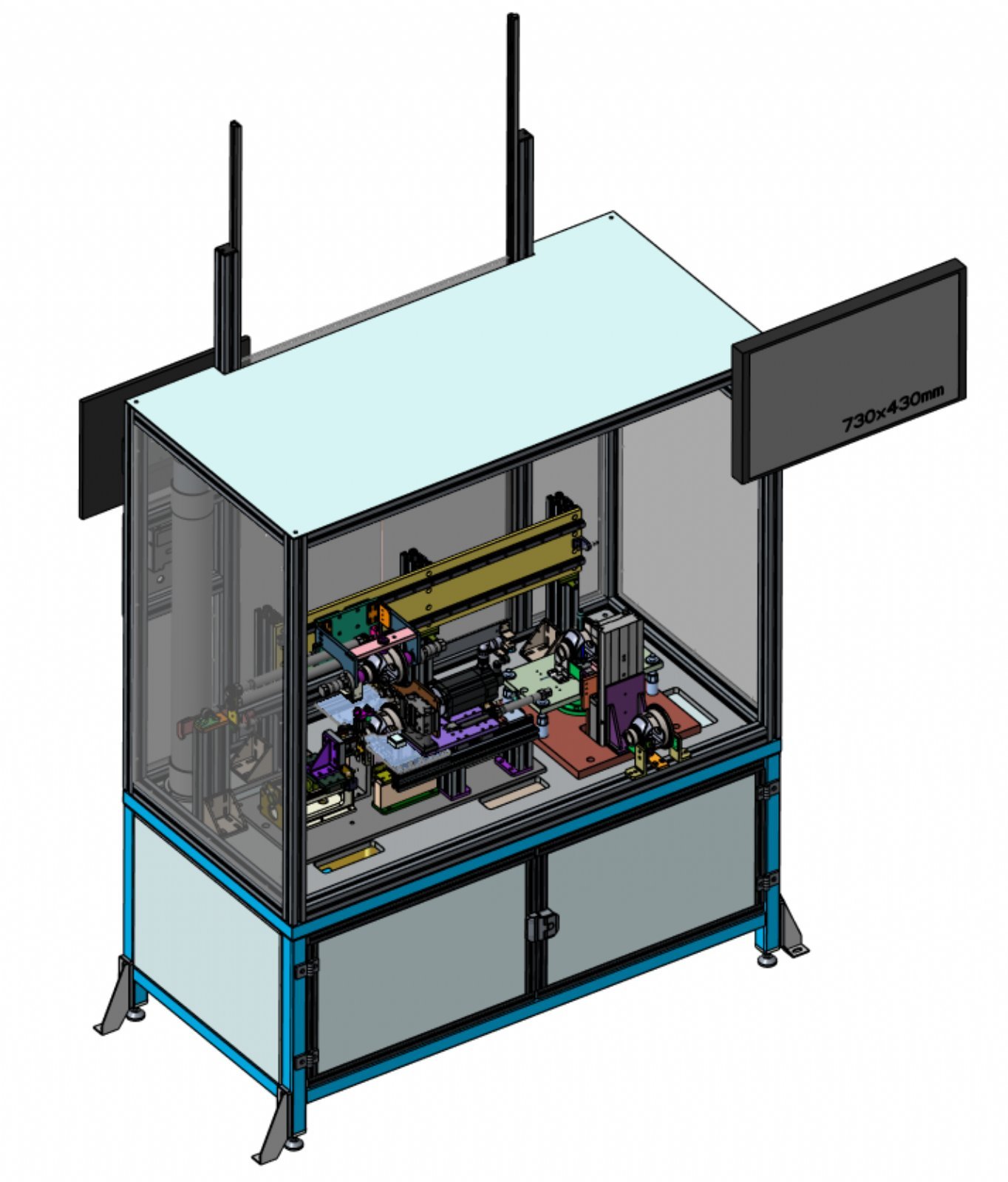

Where precision meets automation.Ensuring

accuracy in every micron — this video showcases our autonomous dimensional

gauging machine, purpose-built for high-precision differential housings.

Designed as a standalone unit, it can easily integrate into automated

production lines via robotic connection.

Here’s how

we achieve world-class quality:

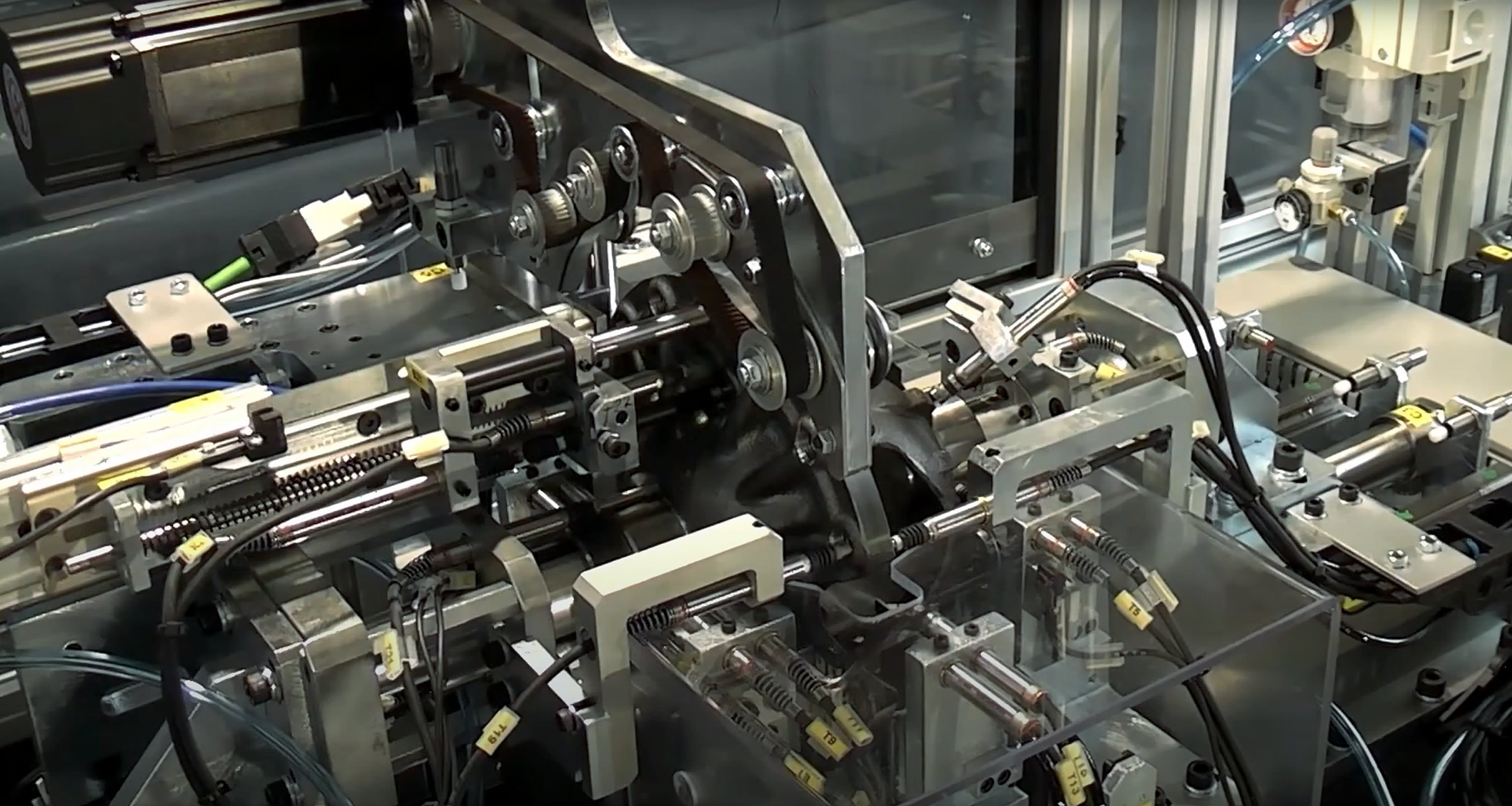

1️⃣Automatic & Precise

Handling: The workpiece is automatically positioned and lowered into the

Inspection Fixture for reliable, repeatable measurement.2️⃣Dynamic Measurement:Using a servo-electric drive, the housing rotates beyond 360° to capture a full feature profile, from which the total deviation is precisely calculated.

3️⃣Ultra-Precision Components: Uses Marposs LVDT RedCrown2™ pencil probes with <0.15 μm repeatability, plus thermal compensation for consistent results.

4️⃣Comprehensive Evaluation: Measures internal/external diameters, cylindricity, runouts, and positional accuracy.

5️⃣Fast & Data-Driven: Each

cycle completes in about 40 seconds, with results instantly displayed,

stored, and analyzed via Marposs Quick SPC software.

At Sinel,

we specialize in custom dimensional gauging solutions — whether for off-line

sample inspection or fully automated production lines.

Interested in exploring how this project could benefit your company?

Let's discuss your specific needs and explore how our solutions can contribute to your success. Allow us to demonstrate what we believe makes us different, to show you why working with a partner is better than working with a supplier.

Talk to an expert